News Story

Terrapin Works Staff Exceed at Capstone Expo

The first annual Design Expo took place on May 1st 2024, where students from the Clark School of Engineering displayed their capstone projects to 1,400 attendees. Staff members from Terrapin Works contributed to three of five awarded teams at the Expo: AquatiClaw (Mechanical Engineering), Subsurface Ice and Terrain In-situ Surveyor (Aerospace Engineering), and Accessible Ventilation Coach for Opioid Overdose Bystanders (Dean's Award.) Engineering Information Technology, Terrapin Works parent department, also created the website for the Capstone Expo.

Terrapin Works employs eighty to one hundred students each semester, who focus on manufacturing in one of several specializations, including 3D printing, electronics, metal machining, and woodworking. Those skills become invaluable during capstones, where students are expected to design and manufacture a product with societal impact.

Accessible Ventilation Coach for Opioid Overdose Bystanders

Kelly Yeung was the team leader for BIOE Team 9: Accessible Ventilation Coach for Opioid Overdose Bystanders, an adjunctive device meant to enable bystanders to provide life saving aid during opioid overdoses. Team 9 was granted the Dean’s Award, the highest honor bestowed during the expo.

The Ventilation Coach underwent four different prototypes before landing on its final design. Much of that prototyping was made possible by Kelly’s ability to rapidly iterate using 3D printers. “Our last prototype used a print in place design, which required a lot of trial and error. This also allowed me to learn more about the tolerances of the Prusas. I believe knowing the manufacturing technologies provided by TW and their different use-cases definitely benefited the team.

"Capstone for Bioengineering was a great experience. I really enjoyed working with my team and applying our skills and knowledge towards solving a real-life problem. What I enjoyed most was working directly with the clinician who proposed the problem. This made the project feel more impactful and allowed us to create something truly novel. My goal after graduating is to work in MedTech, so having this experience really solidified this passion.”

AquatiClaw

The AquatiClaw team “designed a low-cost lightweight underwater manipulator to grab, sample, and inspect various objects. It was designed for use with the BlueROV, but is largely compatible with other commercial submersibles.” Three Terrapin Works employees –Thomas Milne, Odinn Waguespack and Ethan Hays– contributed to Aquaticlaw.

Thomas was responsible for the design of the manipulator arms shoulder joint and the creation of the team's demonstration video. “Having experience manufacturing countless FDM, SLA, and Laser Engraving orders allowed me to have a better understanding of how to design for manufacturing. The three parts I designed for the shoulder didn't require any supports and printed reliably on FDM/FFF 3D printers. We also considered the impacts of supports on the accuracy of our SLA parts, ensuring that no supports would be needed on the interior of the gripper housing where tolerances needed to be tight to create a waterproof enclosure.”

In addition Thomas led the manufacturing of all custom 3D printed components. At the end of the project, the AquatiClaw had 21 components printed using advanced additive manufacturing in the AFL.

Capstone as a whole seemed like an experience which got me ready to face challenges and propose solutions in industry like a real engineer. It helped me tie all my experiences from research labs, Terrapin Works and classes together to deliver a full proposal.

Kruti Bhingradiya

“Overall, it was a brutally tough and incredibly rewarding project. The difficulty of the project and what we got out of it was entirely determined by our drive to be great. One of the other capstone teams consisting of multiple TW employees (Hydro grasp with Wensen, Brandon, Henry, and Sam), pushed us to be better by the quality of their underwater manipulator project. I also found it important to remember that progress is not linear. For us, progress often came in chunks, followed by some obstacles that would hold us back until we could break through and rapidly make some more developments."

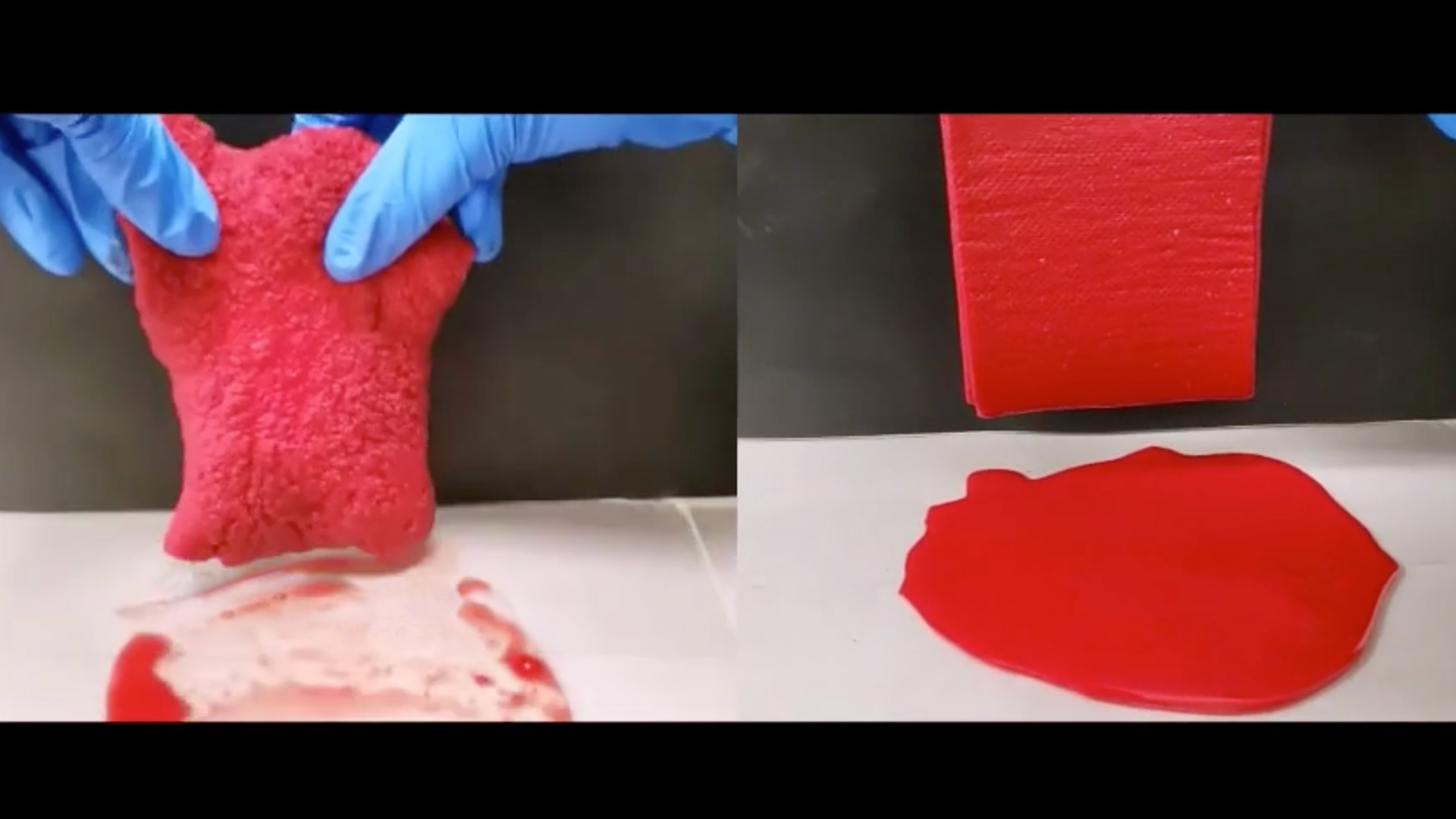

Odinn focused on waterproofing the AquatiClaw and designing the grippers used to manipulate objects. “My capstone experience was great. I think I learned the most from all the mistakes I made during prototyping, and I'm really proud of our final product… My role as a TW staff member was invaluable for my capstone experience. I had to do experimentation with SLA tolerancing to get fully waterproof prints, something that I was only able to do due to my experience working in the lab. I do not think that this project would have been possible without the skills my team received from TW.”

"Design expo was fantastic, there were some amazing teams showcasing, and it was great seeing all the work everyone put into the course paying off. I was particularly impressed by Kelly's team and their project (Accessible Ventilation Coach for Opiod Overdose Bystanders.)"

Ethan led on electronics design. “The second half of the course is where pretty much all the design and prototyping work is done. During this time my main job was electronics and coding. I didn't expect this to be my role, I mostly just fell into it. I was sick for over a week and during this time everyone started work on their own subsystems. So my experience with manufacturing and design wasn't really needed anywhere. This is mostly due to the fact we had so many TW employees on the team. But as it turned out, I had more experience with hobby level electronics than most of the other members. So I spent the majority of my time planning out the circuit, determining which components to use, and writing the scripts… Our project used a lot of electrical components, so I spent a lot of time in the IES (Instructional Electronics Shop.) I used the equipment, borrowed tools, borrowed components, and got advice from staff members.”

"The expo was really amazing. I had been to the previous two design days in the Kim building, and this felt much more grand and official. It gave me a chance to visit my friends and coworkers in other majors, learn about their projects, and see professors I knew who were judges for other majors. I went on a study abroad trip with Natasha Andrade, and she brought up the expo a few times and talked to us about it. I enjoyed getting her perspective on things. The award ceremony felt very official and professional. Overall, I think it was a much better experience than the single major design day.

SITIS

Kruti Bhingradiya and George Tang were on the Subsurface Ice and Terrain In-situ Surveyor (SITIS) team, which was awarded Best in Aerospace Engineering. Kruti has been the lab coordinator for the Fabrication Farm for 3 years, a lab that processes over 50% of Terrapin Works orders. Kruti is on the System Analysis and System Engineering subteam, in addition to being the team lead. “SITIS is 540kg prospector equipped with instruments to collect data and analyze samples from unexplored permanently shadowed regions of moon, Sverdrup-Henson craters.”

Kruti leveraged non technical skills she gained from her time at Terrapin Works. “The leadership and management experience I have gained in past few years at Terrapin Works came in very handy… Capstone as a whole seemed like an experience which got me ready to face challenges and propose solutions in industry like a real engineer. It helped me tie all my experiences from research labs, Terrapin Works and classes together to deliver a full proposal."

Published May 13, 2024