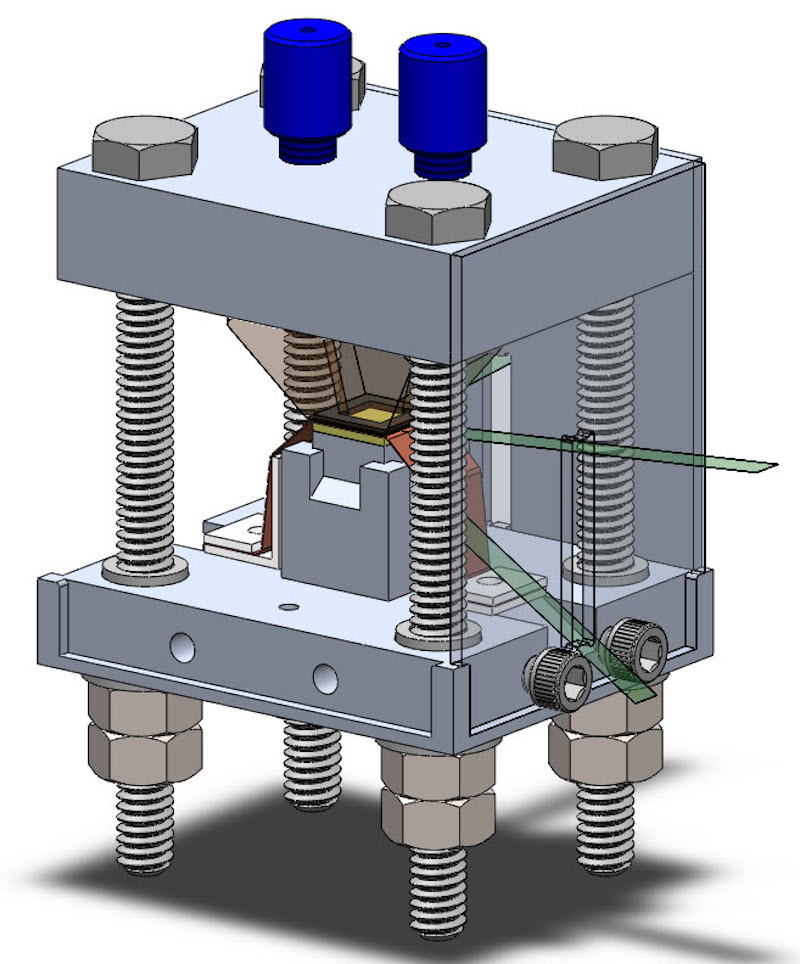

Problem: A NIST researcher inquired the TW Design Team to develop an electrochemical cell to be used in scientific research, specifically in neutron reflectometry experiments on thin films.

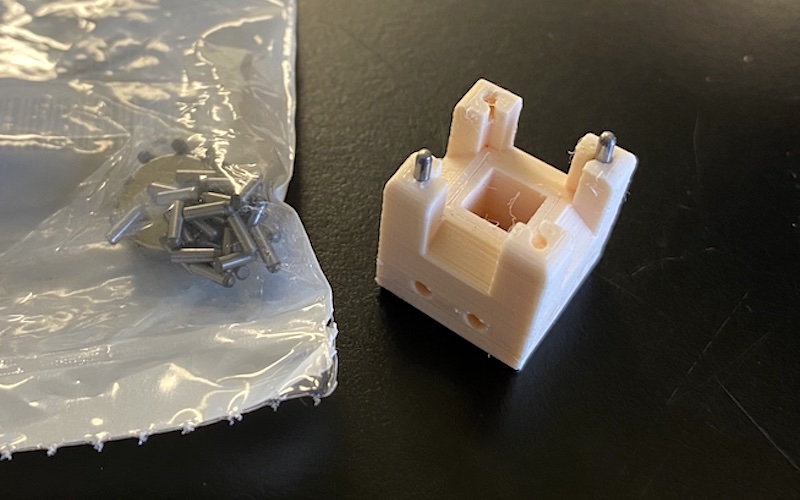

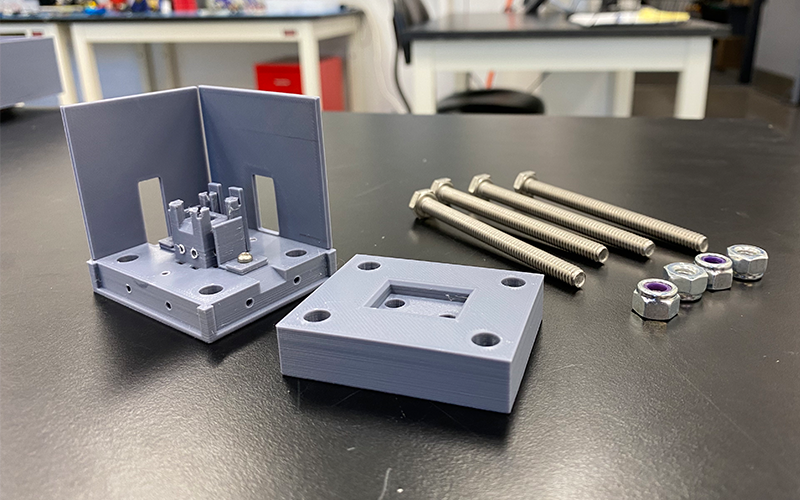

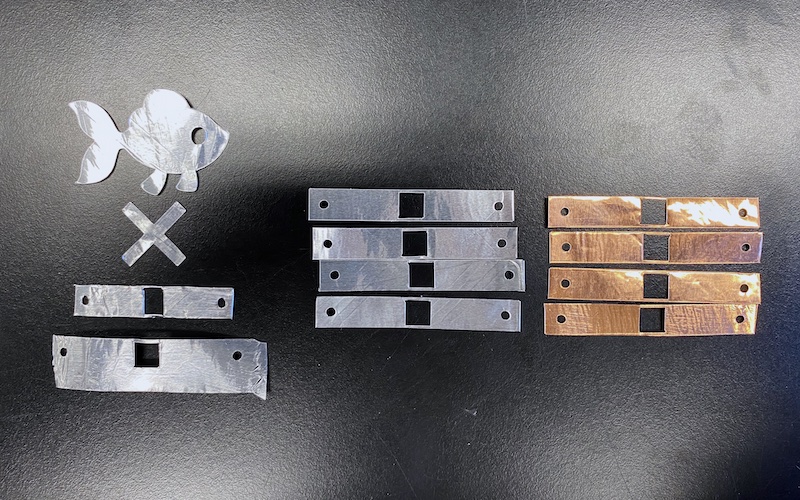

Solution: The TW Design Team created 7 individual parts to clamp and hold the test specimen in the experiment. They utilized various 3D printing technologies for this project, including FDM, SLA, and a desktop CNC machine. The outer box, designed for durability to support the experiment, was crafted using FDM printing. While the inner gray box was produced through SLA printing, creating complex geometries and intricate parts. The material rests on top of a thin copper film that conducts electricity, and was cut using a razor blade on the Cricket. Rectangular slots on the outer walls are designed to allow reflected light to exit. Despite numerous rounds of trial and error to meet the high-detail requirements, the Design Team was able to get a better understanding of the machine limitations and produce a successful prototype.

Technology Types: Fused-Deposition-Modeling (FDM), Stereolithography (SLA)

Equipment: Prusa i3 MK3S+, FormLabs 2 (out of service), Cricket

|

|

|

Top