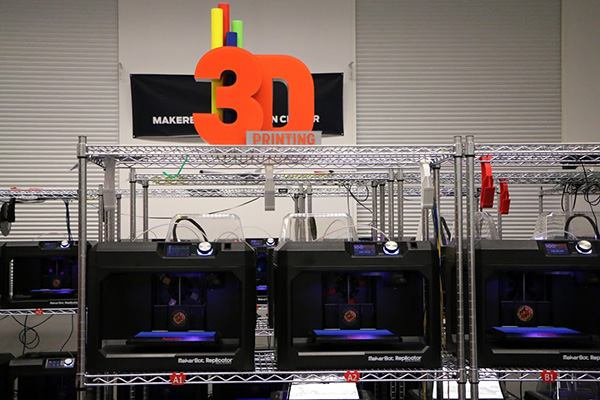

The University of Maryland Fabrication Farm is a 3D printing farm that empowers everyone to invent, innovate, iterate, and replicate.

The Fabrication Farm provides a valuable resource to the campus community: inexpensive, fast 3D printing. The Fab Farm boosts innovation by building capability while concentrating resources and knowledge in one centralized location from which everyone can benefit.

In addition to the Fused Filament Fabrication machines, the Formlabs Fuse 1 printer is capable of creating high-strength objects out of sintered PA12 Nylon Powder. The process utilized by the machine yields solid, isotropic parts that can be utilized in a variety of applications that are benefitted greatly through the use of no support material. As an added benefit, parts produced on the Formlabs Fuse 1 are only slightly more expensive than parts produced on most consumer and prosumer 3D printers, but still much cheaper than many other industrial options.

For Fuse usage:

- Request a Print

- ter.ps/fusetol - Fuse tolerance information

- ter.ps/fusefinish - Fuse surface quality information

Top

Available Equipment

| Equipment Photo | Equipment Name | Service(s) | Materials |

|---|---|---|---|

|

Bambu P1P | Basic 3D printing | PLA, ABS, PETG |

|

Prusa XL | Basic 3D printing | PLA, ABS, PETG |

|

Prusa i3 MK3S+ | Basic 3D printing | Flexible PLA, PLA, ABS, PETG |

| Equipment Photo | Equipment Name | Service(s) | Materials |

|---|---|---|---|

|

FormLabs Fuse 1 & Sift | Advanced 3D Printing | Nylon |