From 3D Systems: The ProX DMP 200 is a production grade 3D printer capable of fabricating metal, metal alloy, and ceramic components

- Wide range of material options

- Research applications for new material development and

- Research applications for heterogeneous integration of multiple metal and ceramic structures within a single device

- Well suited for fabrication of micro-, meso-, and macro-scale devices

- Suited for porous conductive structures for fuel cells and other advanced energy systems

- Also suited for high strength robotic manipulators and locomotion components, complex and high resolution micromolds, and precision medical prostheses

- Limited availability

Specifications

- Max build envelope capacity (W x D x H): 140 x 140 x 125 mm (5.51 x 5.51 x 4.92 in)

- Typical accuracy is +/- 50 μm (+/- 0.002 in) on small parts, +/- 0.2% on large parts

- Repeatability of approximately 20 μm (0.0008 inches)

- Surface finish quality of up to 5 Ra μm (200 Ra micro inches)

- Layer Thickness of 10 - 100 micrometers.

- Smallest feature size: x=100 µm, y=100 µm, z=20 µm

Terrapin Works' ProX 200 uses the following material(s):

- LaserForm Ni625 (B): Ni625 fine-tuned for use with ProX® DMP 200 metal printer producing industrial parts with high heat resistance, high strength and high corrosion resistance. LaserForm Ni625 (B) is especially resistant to crevice and pitting corrosion.

Unfortunately we are unable to accommodate other materials due to the nature of the design of the machine.

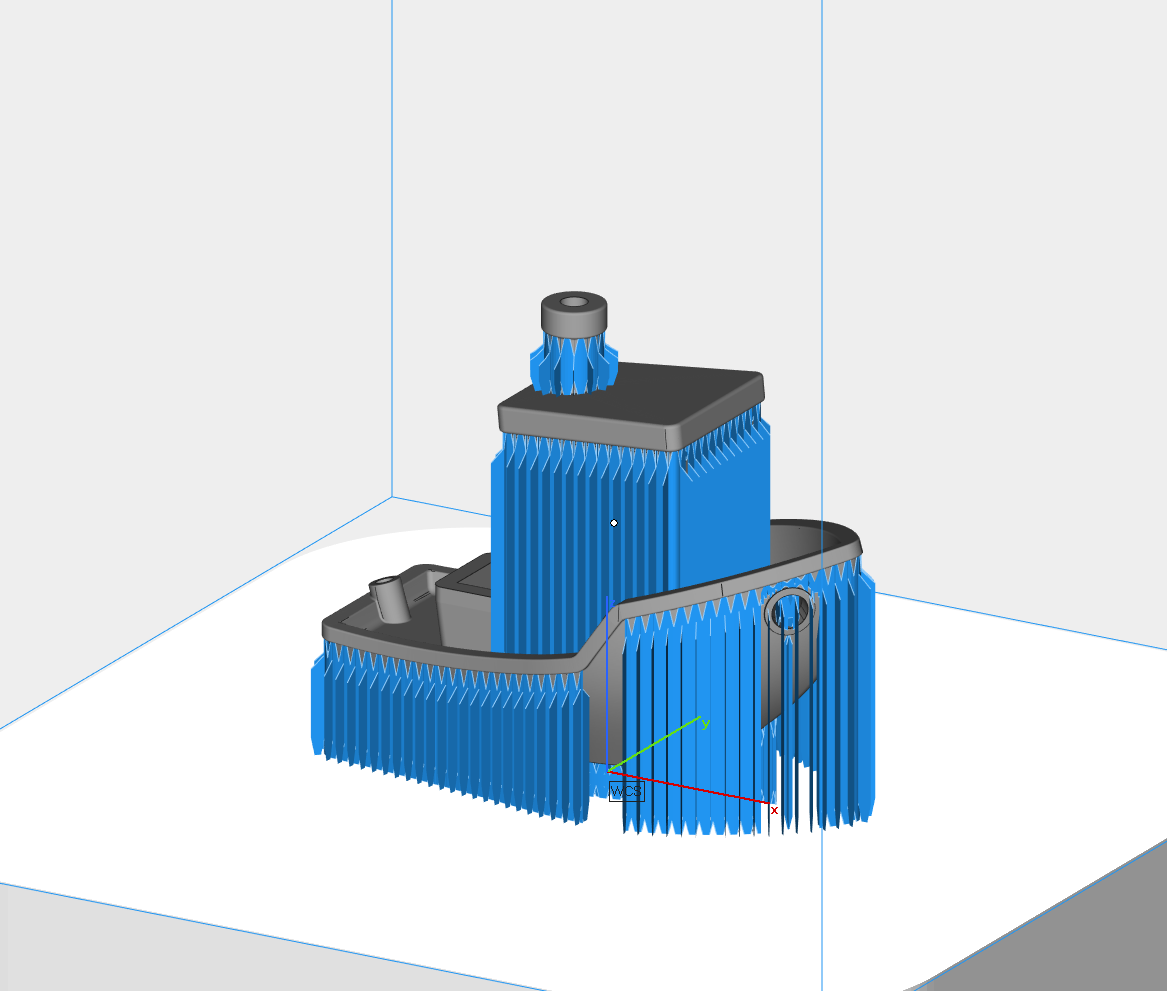

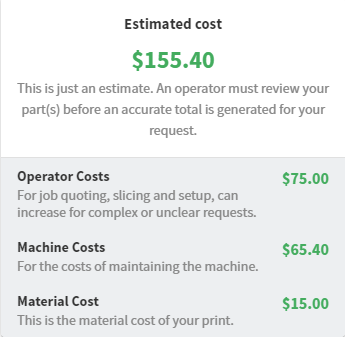

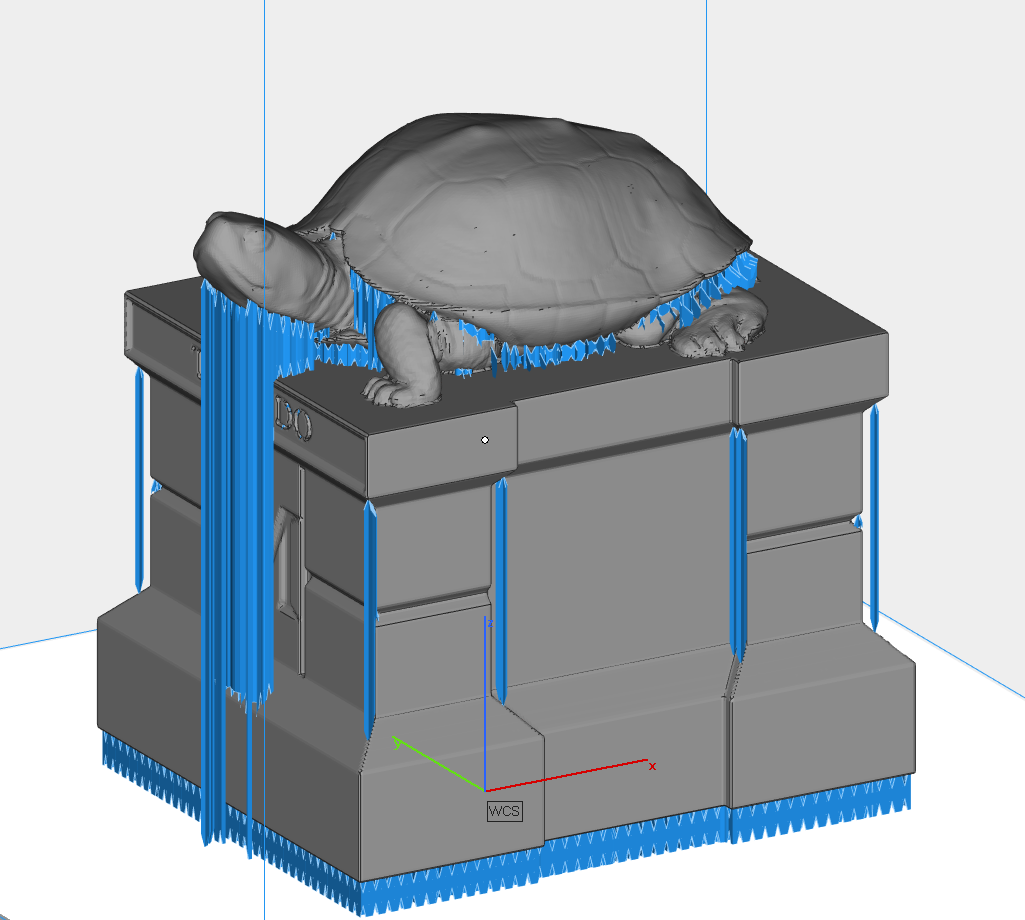

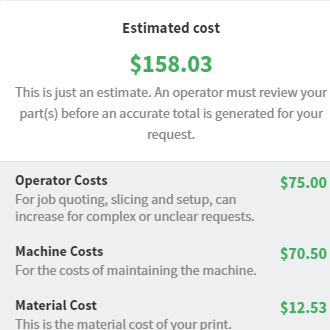

While exact cost may change depending on post processing complexity, geometry complexity, and require timeframe here are a few sample quotes with slices to get an idea of DMLS pricing.

Sample quote for a 60 x 31 x48 mm benchy, sliced in the default orientation:

Sample quote for a 70 x 54 x 68 mm Testudo statue:

To get precise pricing for your part, please contact terrapinworks@umd.edu for a quote on your design.

The slicing and machine interface software are proprietary for the ProX, but design guidelines and overviews on operational processes can be found on our Dozuki page: https://dozuki.umd.edu/c/ProX_200

Top