High-performance laser in compact machine format

The SLM ® 125 is a flexible manufacturing system with a powerful laser. The machine is used in particular for the production of prototypes and qualified components in small series. It processes all SLM ® metal powders, including reactive materials. Processes developed on the SLM ® 125 can later be transferred to larger SLM ® systems. This is particularly interesting for beginners in metal-based additive manufacturing. Research institutes also benefit from the material development module. The SLM®125 is an entry-level machine that offers a printing volume of 125 x 125 x 125 mm, hence its name, and provides more accessibility than other metal solutions. It uses the powder bed laser fusion process, which relies on a standard 400W fiber laser. According to the German manufacturer, the SLM®125 offers 160% more volume than competing solutions, using 80% less powder. This is because the machine uses an optimized gas filtration system that improves the gas flow.

The SLM®125 is compatible with nickel alloys, aluminum, stainless steel, titanium, and chrome-coal, and can process reactive and non-reactive metals. The machine is equipped with a powder screening system to ensure high-quality printing, which separates oversized particles from those ready to be fused.

The SLM®125 is suitable for tooling parts with integrated cooling channels, such as tooling inserts, and is also popular in the medical sector for the production of custom-made implants, among other things. It is an ideal solution for anyone interested in starting industrial metal 3D printing

Specifications

-

Max build envelope capacity (W x D x H): 125 x 125 x 125 mm (4.92 x 4.92 x 4.92 in)

-

There is some volume that is reduced by the build plate and screw holes- consult with TW technicians for details.

-

-

Typical accuracy is +/- 50 μm (+/- 0.002 in) on small parts, +/- 0.2% on large parts

-

Repeatability of approximately 20 μm (0.0008 inches)

-

Surface finish quality of up to 5 Ra μm (200 Ra micro inches)

-

Layer Thickness of 70 - 100 µm.

-

Smallest feature size: x=100 µm, y=100 µm, z=80 µm

Changing materials is not currently supported as of 4/2/25, but we are investigating the right procedures to include this capability in the near future. Please contact terrapinworks@umd.edu if there is a request that requires alternate materials.

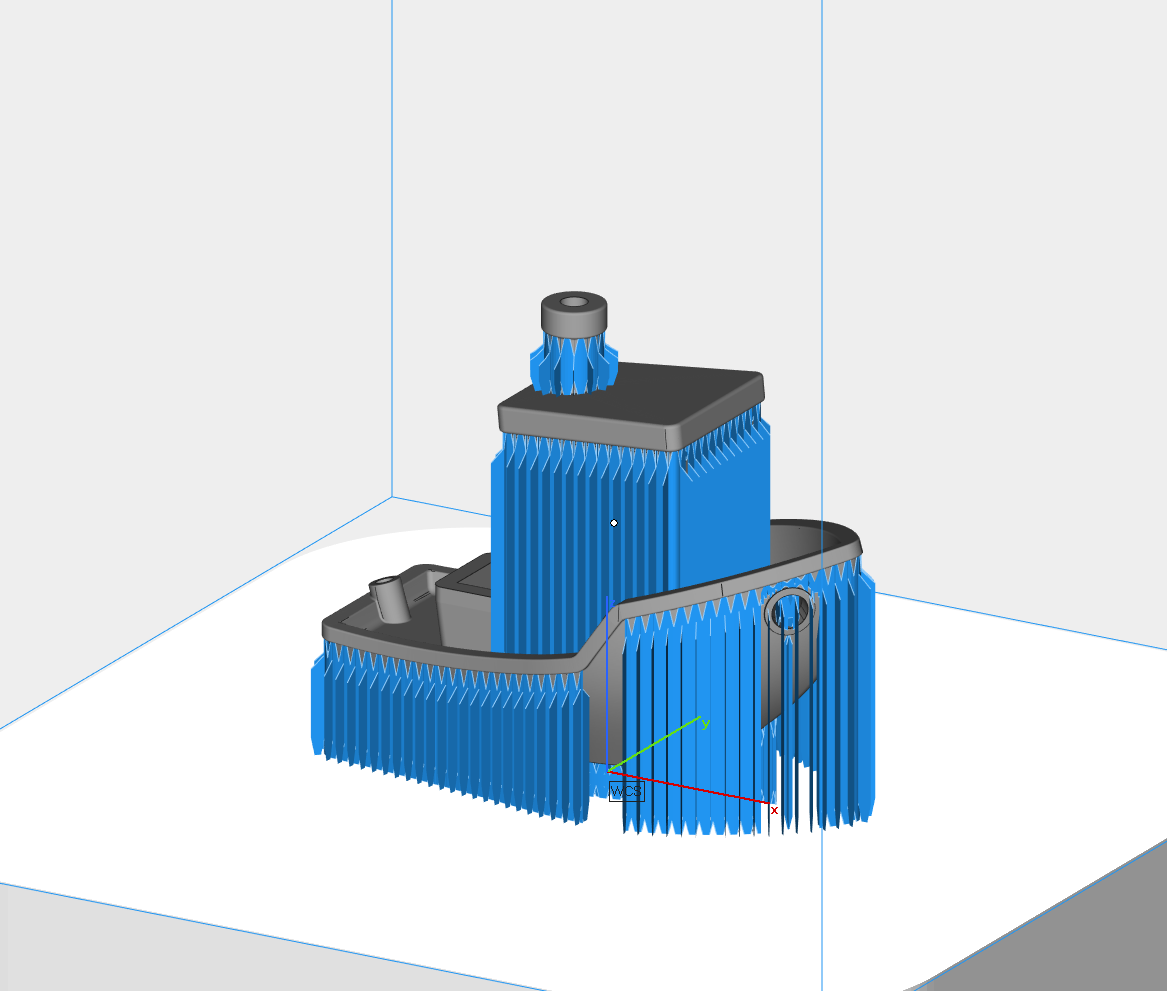

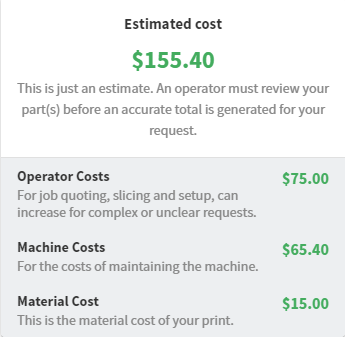

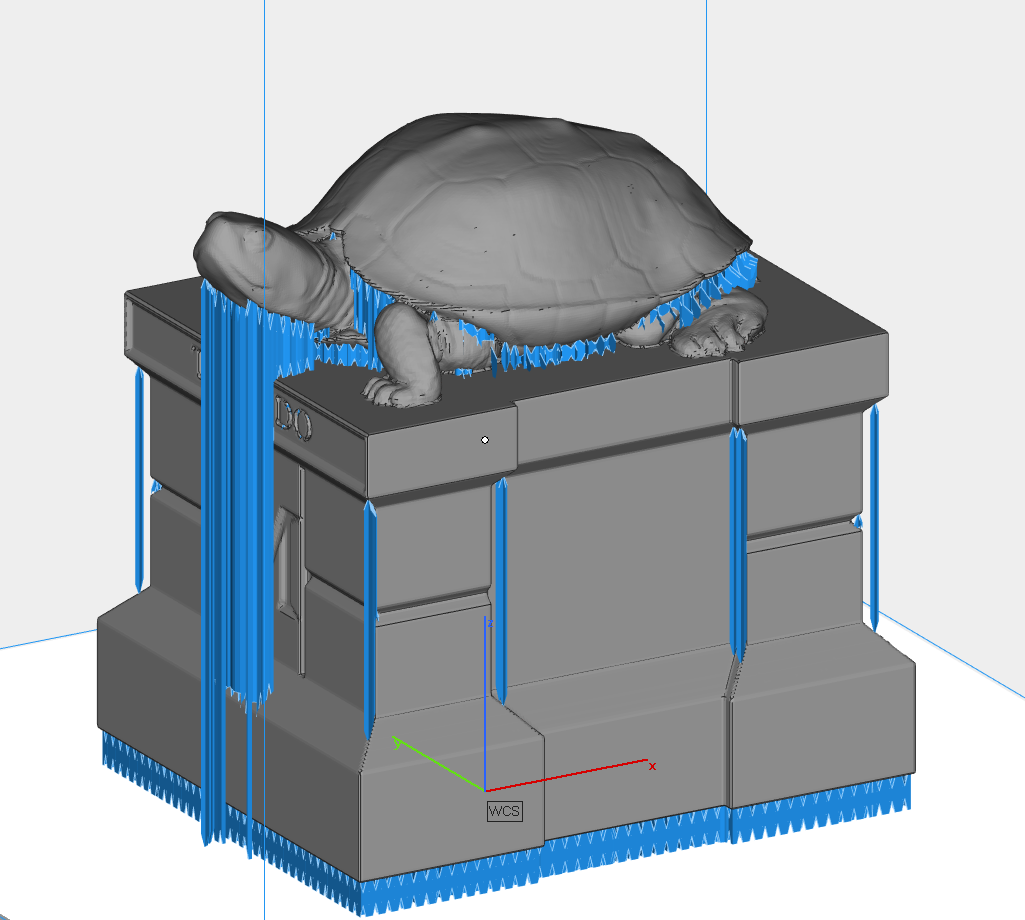

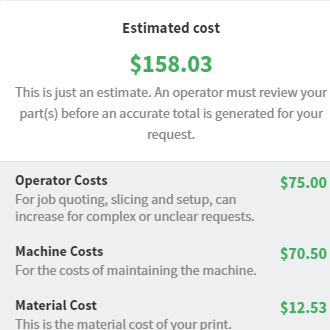

While exact cost may change depending on post processing complexity, geometry complexity, and require timeframe here are a few sample quotes with slices to get an idea of DMLS pricing.

Sample quote for a 60 x 31 x48 mm benchy, sliced in the default orientation:

Sample quote for a 70 x 54 x 68 mm Testudo statue:

To get precise pricing for your part, please contact terrapinworks@umd.edu for a quote on your design.

Top