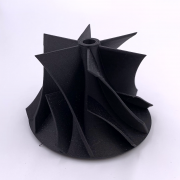

The Mark Two is a professional grade desktop 3D printer built around the Continuous Fiber Reinforcement process to reliably produce strong parts. A hardened extrusion system enables the Mark Two to print Onyx reliably over thousands of print hours. In addition to more common FFF features, the Mark Two has a 2nd-generation fiber reinforcement system that enables you to lay down continuous fiber into parts. Only Markforged composite printers are capable of printing continuous fiber reinforced parts, which can be as strong as machined aluminum.

Build Volume:

320 mm (W) x 132 mm (D) x 154 mm (H). We will only print objects smaller than this volume due to print setup and processing limitations.

Materials :

Detailed Materials:

In order to fully utilize the Markforged Mark 2, two materials must be selected, the Composite and the Inlay. The Inlay provides support to the Composite.

Composite Material Options

- Onyx - a micro carbon fiber filled nylon that yields accurate parts with impeccable surface finish. It offers high strength, toughness, and chemical resistance when printed alone, and can be reinforced with Continuous Fibers to yield aluminum-strength parts.

- White Nylon - an unfilled thermoplastic. It’s a non-abrasive material that is great for ergonomic surfaces and workholding for pieces that are easily marred. It can be painted or dyed.

Fiber Inlay Materials

- Carbon Fiber - ultra-high-strength Continuous Fiber — when laid into a Composite Base material like Onyx, it can yield parts as strong as 6061-T6 Aluminum. It’s extremely stiff and strong, and can be automatically laid down in a wide variety of geometries.

- Kevlar - a specialized Continuous Fiber known for its energy absorption and extreme toughness. When laid into Onyx or another Composite Base material, it yields extremely impact-resistant parts that are nearly immune to catastrophic failure (fracture). It’s perfect for use in parts that are in demanding environments or are subject to repetitive loading.

- HSHT Fiberglass - defined by two characteristics: high strength (nearly equal to 6061-T6 Aluminum) and strength in high temperatures. Though not as stiff as Continuous Carbon Fiber, Onyx parts reinforced with HSHT are strong at both low and high temperatures. As a result, HSHT reinforcement is best used for parts in high-temperature environments like molds, autoclaves, and others.

- Fiberglass - a material capable of yielding parts 10x stronger than ABS when laid into a Composite Base material like Onyx. While being an entry-level Continuous Fiber it provides a more affordable alternative to Carbon Fiber.

Manufacturer URL:

Location:

Technology Type:

Status:

Service(s):

Advanced 3D Printing

Top