Machine Information:

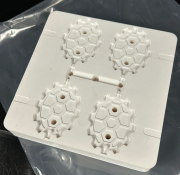

The BOY 22 A PRO is an injection molder specifically designed for reliability in smaller batch sizes compared to its larger counterparts. The fitted screen with Procan ALPHA® 2 Control System allows easy control and access of simple operations and process data. Terrapin Works has developed a system for interchangeable, resin printed, custom designed molds which allow users to make medium batch volume productions for a significantly reduced cost. More details on mold design and material constraints are listed below.

Technical data

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Terrapin Works has also developed user guides working through designing a custom resin printed mold, as well as giving insight as to how the machine is operated. These are available on Dozuki:

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Terrapin Works has also developed user guides working through designing a custom resin printed mold, as well as giving insight as to how the machine is operated. These are available on Dozuki:

Top